Products

The DSF series refrigeration application fully enclosed vortex refrigeration compressor is a refrigeration equipment that integrates

efficiency, energy conservation, safety, and environmental protection. By adopting advanced vortex technology, energy

consumption can be significantly reduced while maintaining high refrigeration efficiency. Suitable for various temperature control

scenarios, such as refrigeration, freezing, etc.

It has the following characteristics and advantages:

1、 Dual flexible design

Ensure longer lifespan and reliability of sealing between vortex discs, better liquid tolerance, and better impurity tolerance

2、 Energy efficiency ratio

Vortex disc running in instead of wear performs better with increasing operating time, resulting in higher volumetric efficiency

3、 Lower noise and vibration levels

The compression chamber is always symmetrical, with low unbalanced stress and high-precision manufacturing process without

the need for vibration absorption devices

4、 Space Age Materials

High strength metal composite bearings with porous permeable bronze PTFE coating with very small friction coefficient

Extend operating time without complete lubrication

5、 Uninstall startup technology

The compression components automatically separate after shutdown to achieve internal pressure balance without the need for

additional starting devices

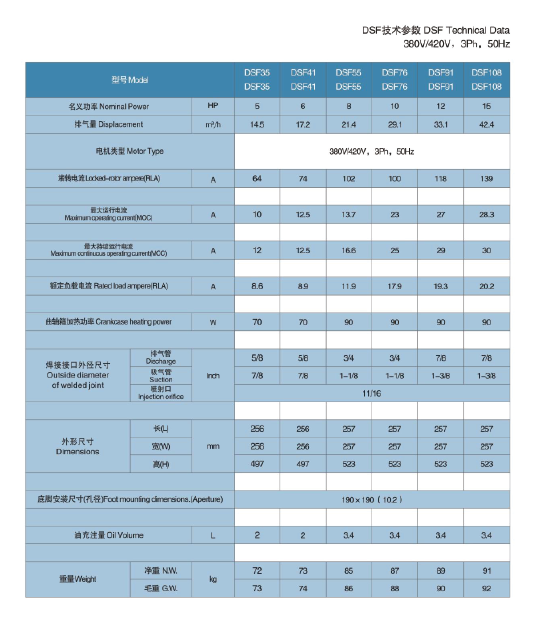

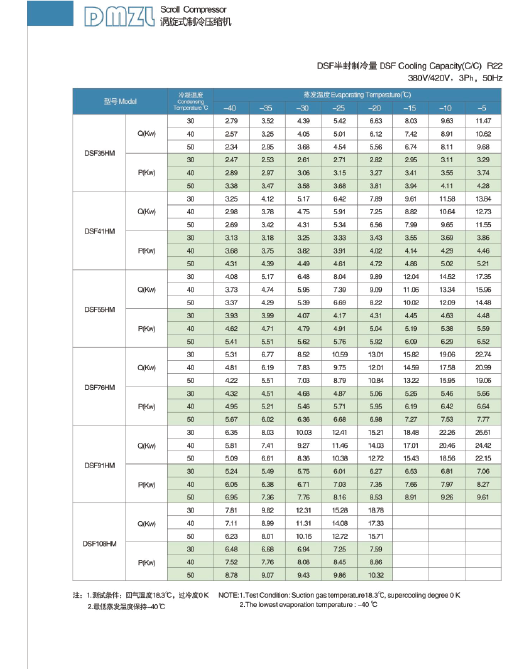

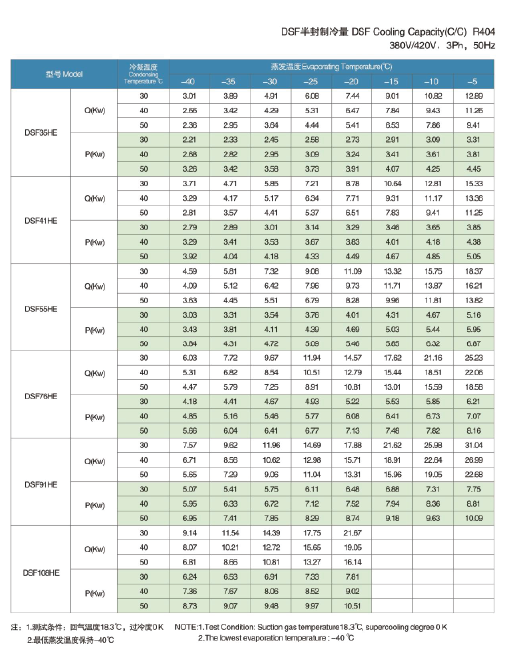

Related technical parameter table:

1. Open box inspection: After receiving the equipment, first check whether the packaging is complete and whether the

components are complete. If there is any missing or damaged, please contact the supplier in a timely manner for replacement.

2. Installation and debugging: Install the compressor in the appropriate position according to the requirements of the equipment

manual, and ensure that the power cord is connected correctly and without errors. Then, necessary debugging work is carried

out according to the equipment requirements, such as adjusting the refrigerant filling amount, setting operating parameters,

etc.

3. Startup and operation: Turn on the power of the device and observe its operating status. After confirming the normal

operation of the equipment, the actual refrigeration operation can begin.

4. Monitoring and maintenance: During the operation of the equipment, attention should be paid to observing its operating

conditions, such as temperature, pressure, and other parameters. Once any abnormal situation is discovered, timely measures

should be taken to handle it. In addition, regular maintenance and upkeep should be carried out on the equipment to ensure

that it is always in good working condition.

5. Shutdown and shutdown: When the equipment no longer needs to run, please turn off the power first, and then follow the

requirements of the equipment manual to shut down. During the shutdown process, it is important to observe the status of the

equipment and ensure that it has completely stopped before proceeding to the next step of operation.

6. Storage and transportation: During the idle period of the equipment, please store it in a dry and well ventilated place,

avoiding direct sunlight and humid environments. During transportation, it is necessary to ensure the integrity of the equipment

packaging and avoid collision and compression.

WARNING!

1. Oxygen pressure testing is strictly prohibited for the compressor unit, and nitrogen pressure testing without a safety valve is

strictly prohibited. Improper use may cause explosions and casualties. The manufacturer shall not be responsible for any

consequences caused by the above reasons.

2. When assembling the compressor unit and installing an oil separator, 1.5 to 2 liters of refrigeration oil (46 #) must be added to

the oil separator. If the compressor freezes up due to insufficient oil due to not adding refrigeration oil, the manufacturer will not

guarantee repair

3. The compressor is strictly prohibited from being compressed or vacuumed by the main engine. When using an oil pump

lubricated compressor, an oil pressure protection device must be installed (the connection device of the oil pressure controller is

shown in the diagram). If the compressor is damaged due to non compliant use, the manufacturer will not provide warranty.

4. It is strictly prohibited to use methanol to absorb moisture, in order to avoid damage to the motor.

5. All compressors must be equipped with electric heaters. When the compressor is restarted after a long-term shutdown, the

crankcase heating function must be used, otherwise it will cause liquid shock and serious damage to the valve plate, connecting

rod, and crankshaft.

6. The refrigerant must be filled into the system from the high-pressure valve (the system must be in a vacuum state). It is strictly

prohibited to add excessive refrigerant from the suction valve during the operation of the compressor, otherwise it will cause

compressor liquid shock, resulting in valve plate and valve plate fracture, connecting rod damage and locking, causing

unnecessary damage to the user.

7. The cold storage system must be clean. If using pipelines, be sure to install an suction filter device on the suction valve. The

refrigeration oil must be kept clean. If you find that the refrigeration oil is insufficient or dirty, please add and replace the

refrigeration oil as soon as possible.

8. The installation of the wiring device must be securely fixed and then insulated with adhesive. During startup and debugging, it is

necessary to check whether the exhaust valve has been opened. Do not open the suction valve too wide, slowly open it after

operation.

Please read the user manual carefully before use, and follow the operating methods indicated in the manual. If the compressor is

damaged due to improper use, the manufacturer will not provide warranty.